- +86 18120750932

- colin@xmsinuowei.com

- www.xmsinuowei.com

With the advent of the era of digitalization, informationization and networking, electronic packaging has put forward higher requirements for miniaturization, integration, multi-function, high speed and high frequency, high performance, high reliability and low cost. LTCC packaging products have obvious characteristics in terms of miniaturization, integration, high speed and high frequency, and high performance, and will continue to develop in the future to maintain technological advantages.

LTCC Technology

However, conventional LTCC packaging products still have deficiencies in thermal matching, heat dissipation, cost, etc., which affect the development of LTCC package products and their application in a wider range of fields. Solving the key problems of LTCC package products in certain application requirements has become a technical problem that needs further research.

High thermal expansion coefficient LTCC package

LTCC packages have ways of increasing integration density, such as high-density wiring and multi-chip assembly. The use of LTCC substrates with high thermal expansion coefficients, selection of appropriate interconnect materials and appropriate processes for packaging are important means to improve the reliability of LTCC package modules applied to PCB masters.

In addition, after using the LTCC substrate with a high thermal expansion coefficient, the metal enclosure can use materials such as AlSi with lower density and higher thermal conductivity, which is conducive to the selection of metal materials and module heat dissipation. The high thermal expansion coefficient LTCC package plays an important role in promoting the application of LTCC in the field of high-speed, ultra-large-scale circuits and matching with PCB mother boards.

High thermal conductivity LTCC package

The development of electronic equipment in terms of miniaturization, multi-function, and high power will further increase the assembly density and power density of the modules in the equipment. Therefore, the effective heat dissipation of the packaged modules is an important factor to ensure the reliability of the equipment. If the LTCC substrate material with higher thermal conductivity can be developed, it will be the best solution to solve the problem of high thermal conductivity LTCC packaging, but there is no commercial LTCC substrate material with high thermal conductivity at present.

Therefore, whether it is to improve the heat dissipation capability of LTCC packaging through substrate materials, thermal conductive materials, micro-channels and other processes, the realization of high thermal conductivity LTCC package will enable LTCC modules to play a greater role in more fields.

Low cost LTCC package

At present, LTCC package products have been used in aviation, aerospace, communication, radar and other fields, but at this stage, high-end LTCC products are still mainly imported LTCC materials, The relevant supporting slurry system is mainly a precious metal material system based on composite materials such as Au, Ag, Pt, and Pd, and the cost is relatively high. Obviously, this is inconsistent with the low-cost development trend of electronic information products, which affects the popularization and application of LTCC packaging products.

Therefore, it is necessary to develop LTCC green ceramic tape and low-cost supporting conductor paste. Cu conductors are not only cheap, but also have excellent electrical, thermal, and soldering properties. By developing highly reliable, low-cost LTCC materials that can be wired with Cu conductors, the cost of LTCC packaging can be effectively reduced.

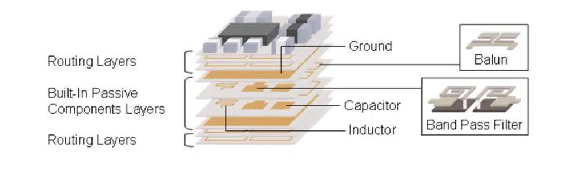

System-in-LTCC package

System-in-Package (SiP) refers to the integration of multiple chips and components in one package to realize a system or subsystem with complete basic functions. System-in-Package strives for higher assembly density and functional density, and can shorten lead times. At present, the LTCC package is usually assembled in the system as a module to realize some functions of the system.

With the successful development of new materials for LTCC substrates (such as materials with high strength, high thermal conductivity, and low cost) and the maturity of advanced packaging and assembly processes, LTCC package will integrate more and more complex components, giving full play to the advantages of LTCC miniaturization, integration, high speed and high frequency, etc., and realize system-level LTCC packaging.

Source: IE electronic

Previous :

Hose clampNext :

The Best Hose Clamps to Secure Pipes and Hoses

Service online